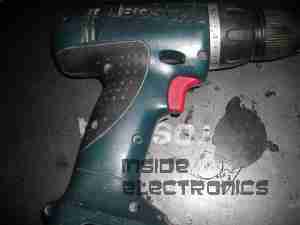

Here is a Bosch 14.4v Professional cordless drill/driver, recovered from a skip!

It was thrown away due to a gearbox fault, which was easy to rectify.

Here is the drill with the side cover removed, showing it’s internal parts. The speed controller is below the motor & gearbox here. The unit at the top consists of a 12v DC motor, coupled to a 4-stage epicyclic gearbox unit, from which can be selected 2 different ratios, by way of the lever in the centre of the box. This disables one of the gear stages. There is a torque control clutch at the chuck end of the gearbox, this was faulty when found.

Here is the drive motor disconnected from the gearbox, having a bayonet fitting on the drive end.

This is the primary drive gear of the motor, which connects with the gearbox.

The motor is cooled by this fan inside next to the commutator, drawing air over the windings.

This is the gearbox partially disassembled, showing the 1st & second stages of the geartrain. The second stage provides the 2 different drive ratios by having the annulus slide over the entire gearset, disabling it entirely, in high gear. The annulus gears are a potential weak point in this gearbox, as they are made from plastic, with all other gears being made of steel.

Here is the charging unit for the Ni-Cd battery packs supplied with the drill. The only indicator is the LED shown here on the front of the unit, which flashes while charging, & comes on solid when charging is complete. Charge termination is by way of temperature monitoring.

Here the bottom of the charger has been removed, showing the internal parts. An 18v transformer supplies power to the charger PCB on the left.

This is the charger PCB, with a ST Microelectronics controller IC marked 6HKB07501758. I cannot find any information about this chip.

Here is a battery pack with the top removed, showing the cells.

This is the temperature sensor embedded inside the battery pack that is used by the charger to determine when charging is complete.