This is the teardown of a Zebra P330i plastic card printer, used for creating ID cards, membership cards, employee cards, etc. I got this as a faulty unit, which I will detail later on.

This printer supports printing on plastic cards from 1-30mils thick, using dye sublimation & thermal transfer type printing methods. Interfaces supplied are USB & Ethernet. The unit also has the capability to be fitted with a mag stripe encoder & a smart card encoder, for extra cost.

On the left here is the print engine open, the blue cartridge on the right is a cleaning unit, using an adhesive roller to remove any dirt from the incoming card stock.

This is extremely important on a dye sublimation based printing engine as any dirt on the cards will cause printing problems.

Here on the right is the card feeder unit, stocked with cards. This can take up to 100 cards from the factory.

The blue lever on the left is used to set the card thickness being used, to prevent misfeeds. There is a rubber gate in the intake port of the printer which is moved by this lever to stop any more than a single card from being fed into the print engine at any one time.

Here is the empty card feeder, showing the rubber conveyor belt. This unit was in fact the problem with the printer, the drive belt from the DC motor under this unit was stripped, preventing the cards from feeding into the printer.

Here is a closeup of the print head assembly. The brown/black stripe along the edge is the row of thin-film heating elements. This is a 300DPI head.

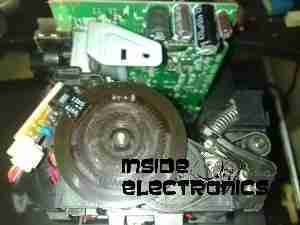

This is under the print head, the black roller on the left is the platen roller, which supports the card during printing. The spool in the center of the picture is the supply spool for the dye ribbon.

In the front of the black bar in the bottom center, is a two-colour sensor, used to locate the ribbon at the start of the Yellow panel to begin printing.

Inside the top cover is the indicator LCD, the back of which is pictured right.

This is a 16×1 character LCD from Hantronix. This unit has a parallel interface.

Front of the LCD, this is white characters on a blue background.

Here is the cover removed from the printer, showing the drive belts powering the drive rollers. There is an identical arrangement on the other side of the print engine running the other rollers at the input side of the engine.

Here the back panel has been removed from the entire print engine, complete with the mains input wiring & RFI filtering.

This unit has excellent build quality, just what is to be expected from a £1,200+ piece of industrial equipment.

The bottom of the print engine, with all the main wiring & PCB removed, showing the main drive motors. The left hand geared motor operates the head lift, the centre motor is a stepper, which operates the main transmission for the cards. The right motor drives the ribbon take up spindle through an O-Ring belt.

Card feeder drive motor, this connects to the belt assembly through a timing belt identical to the roller drive system.

All these DC geared motors are 18v DC, of varying torque ratings.

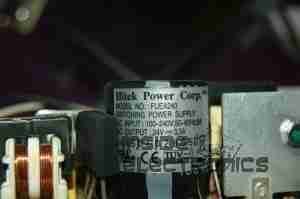

Here is the main power supply, a universal input switch-mode unit, outputting 24v DC at 3.3A.

PSU info. This is obviously an off the shelf unit, manufactured by Hitek. Model number FUEA240.

The PSU has been removed from the back of the print engine, here is shown the remaining mechanical systems of the printer.

A further closeup of the print engine mechanical bay, the main stepper motor is bottom centre, driving the brass flywheel through another timing belt drive. The O-Ring drive on the right is for the ribbon take up reel, with the final motor driving the plastic cam on the left to raise/lower the print head assembly.

The brass disc at the top is connected through a friction clutch to the ribbon supply reel, which provides tension to keep it taut. The slots in the disc are to sense the speed of the ribbon during printing, which allows the printer to tell if there is no ribbon present or if it has broken.

Here is a further closeup, showing the RFID PCB behind the main transmission. This allows the printer to identify the ribbon fitted as a colour or monochrome.

The antenna is under the brass interrupter disc on the left.

The I/O daughterboard connects to the main CPU board & interfaces all the motors & sensors in the printer.

Here is the main CPU board, which contains all the logic & processing power in the printer.

Main CPU. This is a Freescale Semiconductor part, model number MCF5206FT33A, a ColdFire based 32-bit CPU. Also the system ROM & RAM can be seen on the right hand side of this picture.

Bottom of the Ethernet interface card, this clearly has it’s own RAM, ROM & FPGA. This is due to this component being a full Parallel interface print server.

Top of the PCB, showing the main processor of the print server. This has a ferrite sheet glued to the top, for interference protection.