Regular readers might remember a previous post about the fiasco we have had with a hydraulic generator, and in particular one person by the name of Mike Webb.

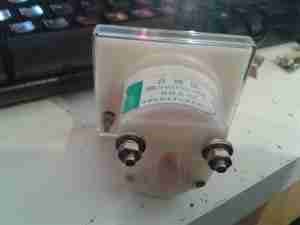

Well here we are a year down the line. The generator still doesn’t function properly, as other things have taken priority, but this is being remedied this week with a replacement hydraulic powerhead. (Correctly sized to 6cc this time, not 11cc).

I even finally got a response from Mike, most likely due to my previous post & the negative publicity that would have brought. In July Mike wrote this:

Good Morning Ben,

I have read your article on the above website, not entirely sure what I can say.

I do however sincerely apologise for the way I handled things, I could give numerous reasons, but I guess they are not your concern, I behaved badly and I am disappointed in myself for treating anyone in this way.

The business has now folded, the domain name www.hydraulicgenerators.co.uk and related products are now owned, manufactured and sold by another company.

My only hope now is that I can in some way repair the damage that has been done and hope that somewhere within yourself you can find a way to accept my apology and forgive me, I am genuinely not a bad person but circumstances outside of my control at the time led me to act in an inacceptable way.

I can understand how you feel, I was defrauded out of a considerable amount of money a while ago and seeking revenge has not been far from my mind for a considerable time, but it won’t get my money back, it won’t undo the damage that has already been done and whilst I might feel better about it for a short while, I have found it difficult from a personal perspective, as, whilst you may cast aspersions about me, my conscience and I do have one just won’t allow me, I can’t help myself from thinking of the other people that would be impacted upon that are otherwise innocent and I know in this particular instance there are several.

I can only hope that you accept my most sincere apology.

Right then. Where should I begin.

No Mike, I will never EVER forgive someone for, what was in my eyes, a deliberate act of fraud & a complete refusal to co-operate.

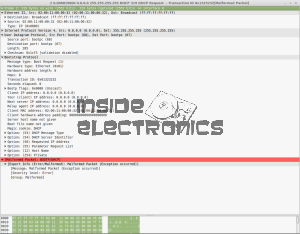

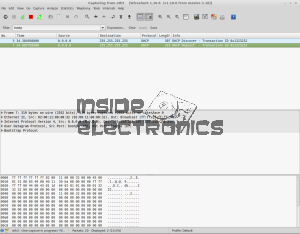

Now, being the resourceful person I am, and my ability (like anyone else with brains), to find out the registrar of domain names, have discovered the man is yet again lying. Company folded? I think not my son.

Two other domain names have popped up with Mike’s name on the Registrar details:

ukgenerators.co.uk

shop4generators.co.uk

(For completeness, here are the full registrar details, just in case things change after I publish this. This information is correct as of 9/12/14)

Domain name:

ukgenerators.co.uk

Registrant:

Mike Webb

Registrant type:

UK Individual

Registrant’s address:

<REDACTED>

Data validation:

Registrant contact details validated by Nominet on 10-Dec-2012

Registrar:

LCN.com Ltd [Tag = LCN]

URL: http://www.lcn.com

Relevant dates:

Registered on: 06-Feb-2004

Expiry date: 06-Feb-2016

Last updated: 16-Jan-2014

Registration status:

Registered until expiry date.

Name servers:

ns1.hostpapa.com

ns2.hostpapa.com

WHOIS lookup made at 16:56:14 09-Dec-2014

Domain name:

shop4generators.co.uk

Registrant:

Mike Webb

Registrant type:

UK Individual

Registrant’s address:

The registrant is a non-trading individual who has opted to have their

address omitted from the WHOIS service.

Data validation:

Registrant contact details validated by Nominet on 10-Dec-2012

Registrar:

Webfusion Ltd t/a 123-reg [Tag = 123-REG]

URL: http://www.123-reg.co.uk

Relevant dates:

Registered on: 02-Jun-2005

Expiry date: 02-Jun-2015

Last updated: 27-Jun-2013

Registration status:

Registered until expiry date.

Name servers:

ns1.hostpapa.com

ns2.hostpapa.com

WHOIS lookup made at 16:55:43 09-Dec-2014

Now for someone who is obviously attempting to tell me that he has no money or resources to reimburse us for the utter hell we have been put through in this situation, seems to be doing pretty well for themselves, in the same business that has apparently ‘folded’.

You have a shiny new logo & business name, and yet apparently have ceased trading?

Now, having been part of a firm during a takeover/company sale, domain names are usually immediately transferred into the name of the buying company. Not in this case it seems. All domains are still registered to you.

Your LinkedIn account still has you as being in the business, along with your Twitter account & YouTube account.

Not to mention, that one one of the aforementioned sites (the original hydraulicgenerators.co.uk), Mike’s E-Mail address is still very much visible on the front page E-Mail Link!

Despite all this evidence of continued trading, according to Companies House, the company is in fact in liquidation: http://data.companieshouse.gov.uk/doc/company/06770818

If this is the case, then Mike Webb is in fact operating illegally.

Mike, if you do read this, I AM NOT AN IDIOT. All I asked was that you put things right, so we would have a WORKING GENERATOR.

So far all this has cost is time & money, and I certainly don’t like being conned.

However I feel it is my duty to make sure that anyone who ever has the misfortune of dealing with you knows exactly what you have previous form for doing.

Legal notice:

All information contained in this post is correct as of 9/12/14. Information will be kept up to date & factually correct to the best of my ability.

Stay tuned for the final chapter in getting this generator fitted & working.